Hurricane High Performance connecting rods - Process of machining rods

illan zhang

hurricanerods.com

2017-09-19 10:13:15

|

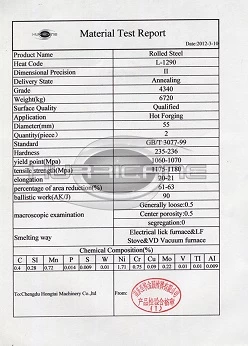

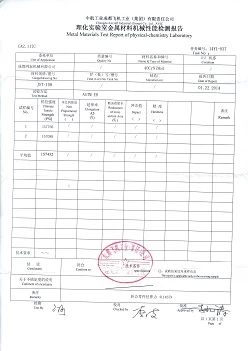

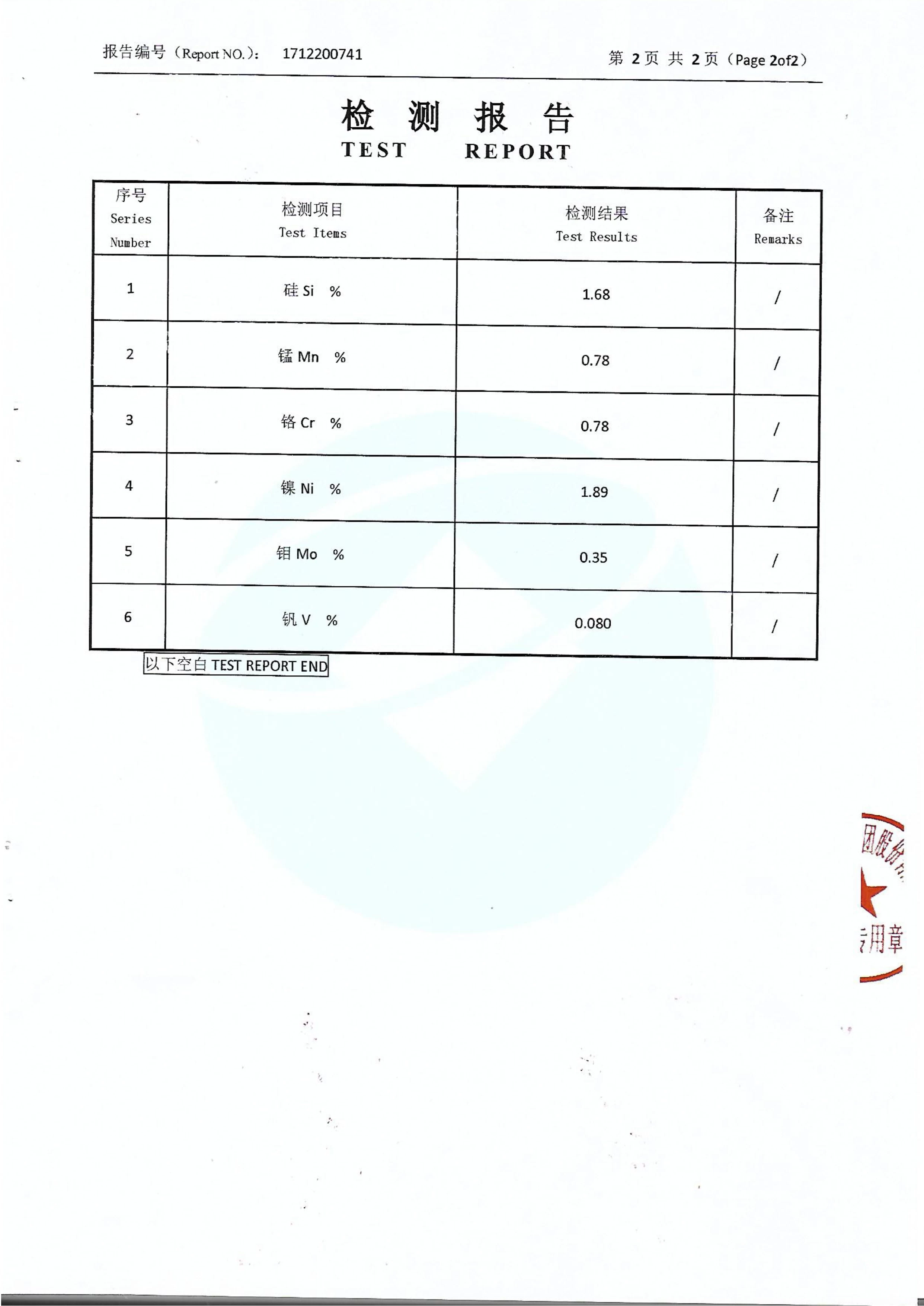

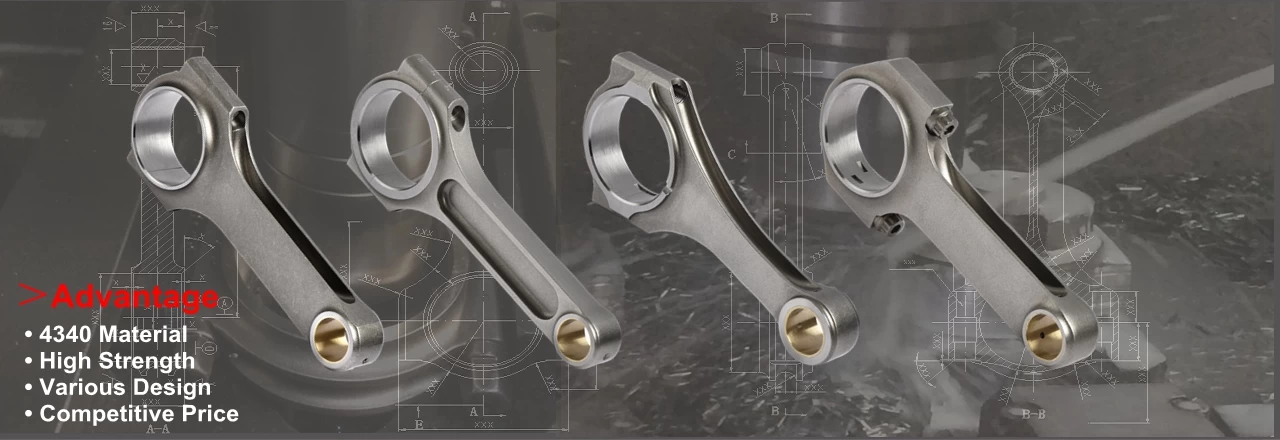

Today racers say an engine is only as reliable as its weakest link. The connecting rods that join the pistons with the crank can be a strong link or a weak link depending on the rods that are used. Most late model stock engines use powder metal rods. As a connecting rods factory, Established in 2000, Chengdu Hurricane Speed&Performance Auto Parts Co., Ltd., have grown to be a professional enterprise in performance auto parts after 17 years' hard-working. All Hurricane connecting rods are Computer Controlled Numeric(CNC) machined and shot peening, using material: 4340 steel, 40CrNiMoA(US) or EN24(EU). Main rods includes: |

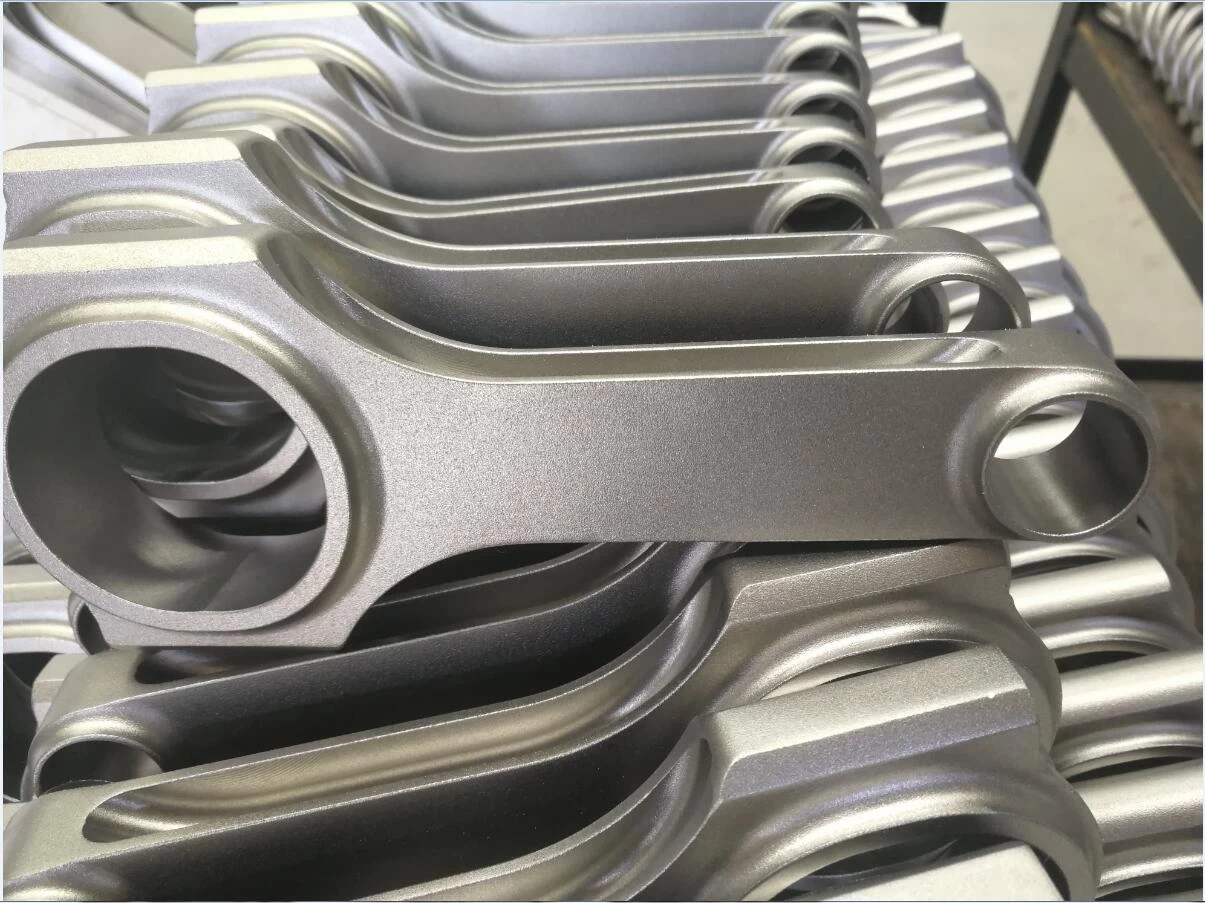

Here in the following process of pictures are the 13 major operations undertaken in the production of Hurricane Speed&Performance:

forging die, generally, we will develop a die for common rods, like duramax diesel connecting rods, Ford 7.5L/460 Connecting Rods, Toyota 2jzgte 4340 Forged Connecting Rods, Honda K20 Connecting Rods, subaru ej20 rods; this way is suitable for common rod with a large a large number. |

Hurricane’s connecting rods are formed from 4340(40CrNiMoA or EN24) steel bar. Cut into lengths they are conveyed to an induction heater. |

In a malleable, plastic condition, not a molten state, the material is handled by tongs and placed in each of con rod impressions carved into a die block. As the hammer runs the hammer, he displaces the soft, white hot metal into each impression, gradually forming the connecting rod. The hammer, which imposes a force of 3,000lbs, impacts the material one strike per second. Three strikes of the hammer and the con rod is forged. |

After the hammer process, conveyor belt and piercing, material of connecting rods are formed. |

The first machining operations include face milling, grinding the big ends and small ends. |

The next operation is to drill bore of the big and small ends, which acts as a reliable locator in all process. |

Then machine the outside surface of the beam to size and complete the recessing operation with a ball-nose end mill, giving the H beam rod its configuration. |

Burring, polishing,(remove burrs and make surface smooth) and shot blasting (Small ball hit surface and make them on surface, increase rods strength with Small ball) are all crucial operations in the making of a competition connecting rod. |

Next step is to separate the rod beam from its cap. |

The side of shoulder is also used for permanent identification marks, used specifically for re-uniting the rod and its cap after the parting tool makes it cut. |

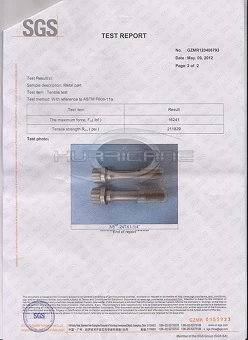

Bolt holes are bored 3/8in or 7/16in. 3/8in option is favored for 4 Cylinder and 6 Cylinder engines, 7/16in potion is favored for 8 Cylinder engines of many race car. |

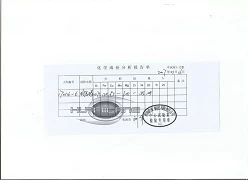

Press with an bronze alloy bushing QAL10-3-1.5, Main Chemistry: Al (Aluminum):8.5-10.0 Mn (manganese):1.0-2.0 Fe (Iron):2.0-4.0 Cu (Bronze )). The bushing, which is initially longer than the finished size, has a interference fit and is press-fitted into place. |

Honing the big and small ends, make all to use sizes. |

Our company video upload on Youtube also, which help you understand them easily, link:

https://www.youtube.com/watch?v=Xb6bSVAMHzI

https://www.youtube.com/watch?v=Xb6bSVAMHzI

-Connecting-Rods-Custom-conneting-rods.jpg.webp)