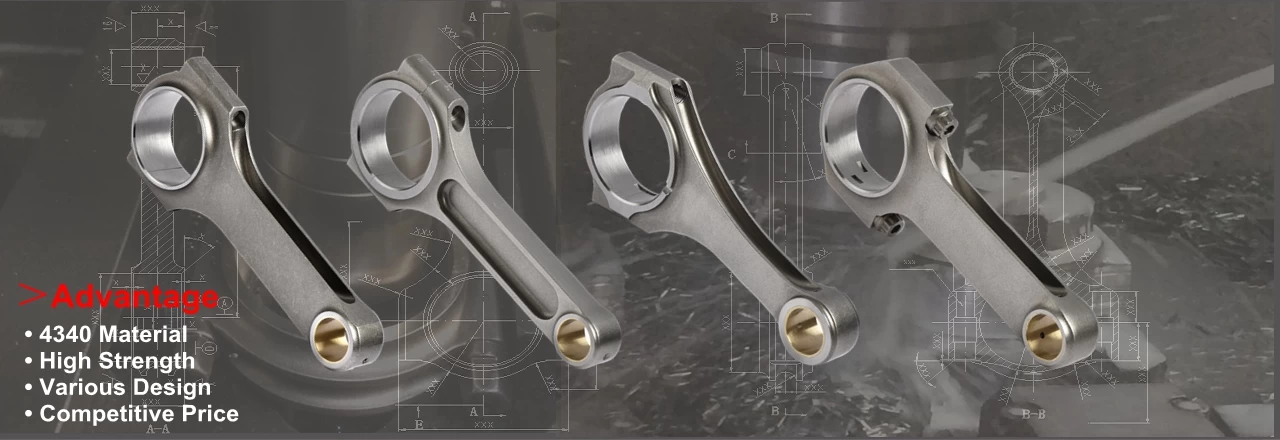

The difference of the connecting rod manufacturing process: Forged vs Billet

Rebeca Yu

http://www.stangtv.com/tech

2017-05-30 22:40:17

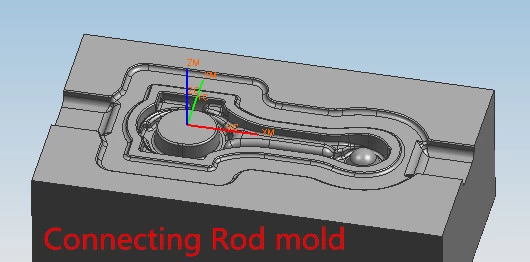

Forging

Forged connecting rods rely on die. A blank piece of metal is heated to a temperature where it is malleable and then forced into the die using high pressure, to make the metal take the shape in the form of a raw connecting rod, and then goes to final machining.

Billet

Billet connecting rods made from a single piece of flat forged steel. The manufacturing process of billet rod does not rely on retooling or die, so its designs can be easily changed according to customer's requirements, include strength , weight, appearance design ,specifications customs etc. Since billet rods are often produced in smaller batches or in custom configurations, more time would be needed in creating the design, machine setup and final finishing, and additional labor would be involved, billet rods would be more expensive than a forged rod of the same material. But when need to develop a new rod model to expand market , billet rod is still a good choice .

Note : Some description from the article in http://www.stangtv.com/tech-stories/engine/

-Connecting-Rods-Custom-conneting-rods.jpg.webp)