-

Do you offer OVERSIZED RODS?

-

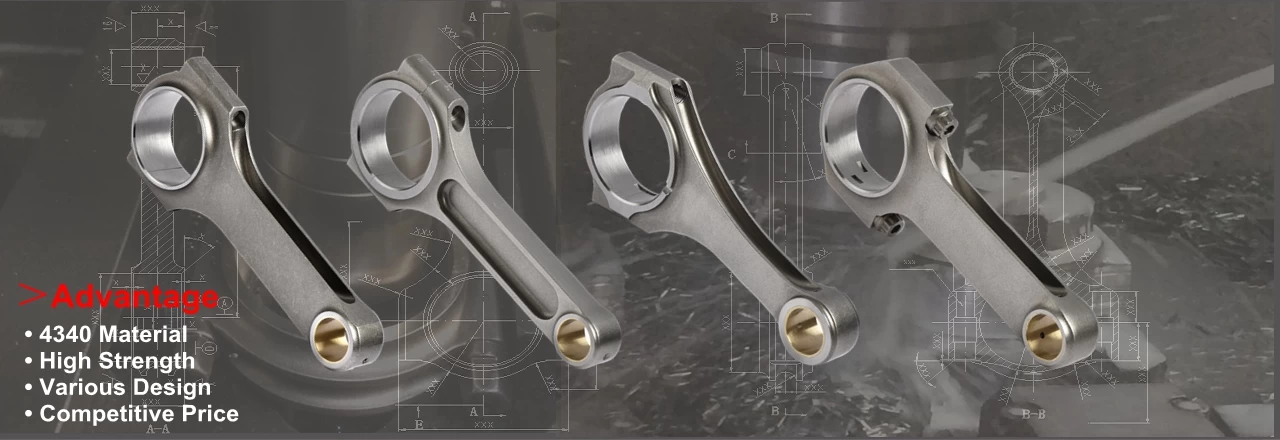

Yes, Rods which are larger than our forging either in length or width, can develop a new die to suit your requirements, or also can be made from billet material. Oversized rods are quoted per order and must be paid in advance. Welcome to leave message to our skilled staff.

-

What is the difference between Hurricane Replacement ARP2000 bolt and Original ARP bolt?

-

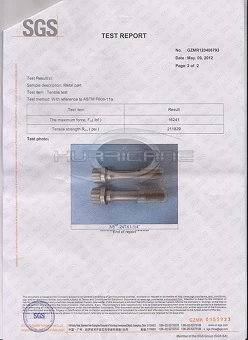

ARP8740 bolt 180,000PSI(YIELD STRENGTH) 200,000PSI(TENSILE STRENGTH)

Hurricane Replacement ARP2000 3/8 bolt 211,829PSI(TENSILE STRENGTH)

ARP 2000 bolt 200,000PSI(YIELD STRENGTH) 220,000PSI(TENSILE STRENGTH)

ARP L19 bolt 220-230,000PSI(YIELD STRENGTH) 260,000PSI(TENSILE STRENGTH)

CUSTOM AGE 625+ bolt 235-255,000PSI(YIELD STRENGTH) 260,000 PSI(TENSILE STRENGTH)

ARP AERMET bolt 260-280,000PSI(YIELD STRENGTH) 290-310,000PSI(TENSILE STRENGTH)

-

What is the bolt torque required on rods?

-

Hurricane Replacement ARP2000 5/16-1.500" Bolts Torque 45N*m

Hurricane Replacement ARP2000 3/8 -1.600" Bolts Torque 75N*m

Hurricane Replacement ARP2000 7/16-1.600" Bolts Torque 95N*m

-

Can I buy connecting rod and bolt separate?

-

Yes, Of course.

-

Could you put my logo on connecting rods?

-

Yes, of course, hurricane factory provide laser logo printing service.

-

What is your connecting rod MOQ, Could you accept customized connecting rod order?

-

MOQ:100 pieces and Yes,there are 2 ways to start business:

1.Provide used sample or full drawing.

2.Download and Fill in Hurricane_Client_Conrod_form.doc at our download page.

If you still have any concerns,welcome to contact us online.

-

What Horsepower Ranges hurricane connecting rods make?

-

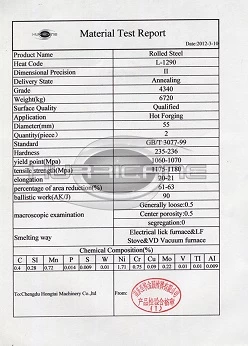

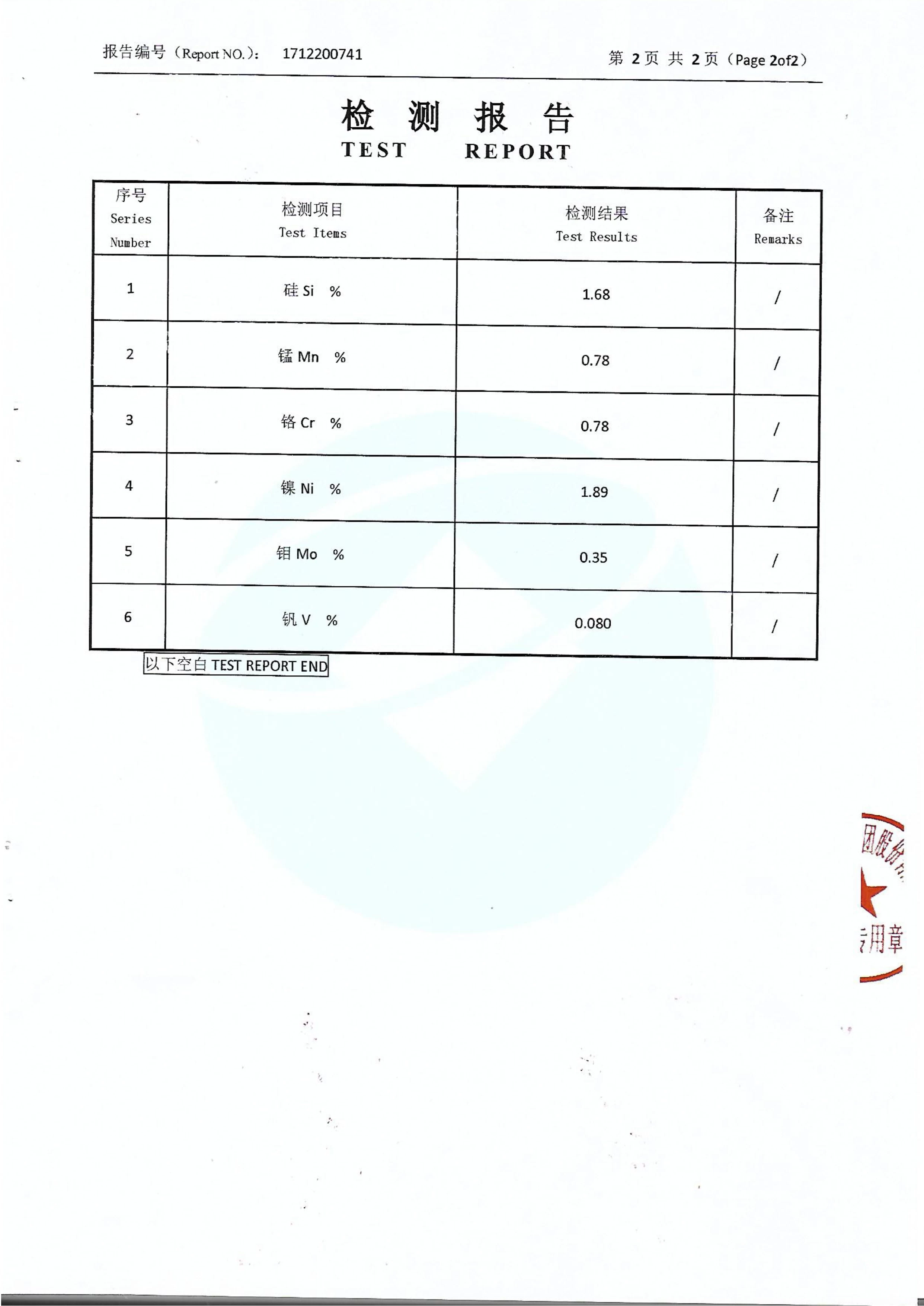

Material: forged 4340 steel

H beam: 150HP per rod

X beam: 175HP per rod

I beam: 200HP per rod

-

What's your connecting rod balance weight?

-

Balance weight +/-1g per set

-

How to connect cap with rods?

-

We use precision alignment sleeves dowel. material:40Cr, HRC40-42

-

What’s your pin bushing material?

-

Material:QAL10-3-1.5 width:0.6mm-0.8mm. Elements: Al (Aluminum):8.5-10.0; Mn (Manganese):1.0-2.0; Fe (Iron):2.0-4.0;Cu (Bronze)

-

What is your connecting rod tolerance?

-

Main size: Center to center length: +/- 0.05mm; Big end bore:+ 0.013mm; Small end bore:+ 0.005mm; Big End width: +/-0.02mm;

Pin End width: +/-0.05mm; No note tolerance:+/-0.15mm

-

What's heat treatment temperature when forming forgings( blanks)?

-

Degree Centigrade:860℃-880℃

-

Can I order a single connecting rod as sample to check quality first before cooperation?

-

Yes, Of course. Please leave us message with which engine model and beam you are interested.

-

Can I order one set connecting rod for my personal engine build?

-

Yes, if we have available stock, then hurricane could supply MOQ in 1 set, please feel free to check stock with hurricane sales team.

-

What is rifle drilling?

-

Rifle drilling also called Forced Pin Oiling(FPO), it means oiling channel from big end to piston pin. rifle drilling increases wrist pin longevity by providing additional lubrication, hurricane rifle drilling application is available in all of our 4340 connecting rods and sold separately, please contact us for more information.

-

What’s your rods material and hardness?

-

Material: 4340 forged steel/40CrNiMoA/EN24. Heat Treatment: HRC34-38

-

How many PSI your connecting Rods hold?

-

Test method: ASTM E8,standard H-beam connecting rods Average reach :15000-1600PSI, you can check our certification page for test report.

-

What depth is the Nitride hardness on the crankshaft journals?

-

The crankshaft journal nitride hardness depth is 0.3mm to 0.5mm.

-

Are you able to offer micro-polishing finish of the crankshafts journals?

-

Yes, After Nitriding treatment, Cranks journal will have micro-polishing treatment

-

What is your crankshafts balance weight?

-

Hurricane crankshafts balance weight is 6g.cm

-

What kind of heat treatment you use on crankshaft? Induction or Ionitriding?

-

Ionitriding

-

What is your Bob weight of Chevy series cranks?

-

Chevy 350/353 bob weight:1855g, 350LW/353LW:1820g, 350LA/353LA:1710g, 400:1900g, 400LW:1820g, 454:2300g, 346/LS1:1800g

-

What is your test condition for crankshaft balance weight?

-

On condition 700-1000RPM/min, unbalance remaining: 6g.cm

-

How to keep crankshaft balance weight?

-

Forged crankshaft use balance hole to keep balance weight, Billet crankshaft keep balance weight by design and manufacture perfect crankshaft fan plate , it is keep balance in the process of high speed rotation. Also the billet crankshaft surface are very smooth and beautiful, no balance hole.

-

Billet Vs Forged crankshaft

-

You can check the compared difference at our News Page: https://www.hurricanerods.com/news/Differences-Between-4340-Forged-Steel-Cranks-and-4340-Billet-Steel-Cranks.html

-

Could I make custom crankshaft?

-

Yes, Of course, we will required your used sample or full drawing for correct quotation. If you want to get an estimate price first, please check our News page: https://www.hurricanerods.com/news/Hurricane-Custom-Crankshaft-Information.html and then contact hurricane sales team with the required main dimensions, we will get back to you within 24 hours.

-

Will you do inspection on CNC machining processes?

-

Yes, For connecting rod, we will do blank dimension Inspection, Tolerance Inspection, Machining Precision Inspection and Balance Weight Inspection.

For pistons, we will do blank dimension Inspection, Tolerance Inspection, Machining Precision Inspection, Ellipticity Inspection and Piston Balance Weight Inspection.

-

When would the product finish if i place order?

-

For Custom and Batch orders, if mould and blank avaliable,Connecting rod lead time: 60-70 days,Piston lead time:45-60 days,Forged half finish machine crankshaft lead time: 80-85 days, Billet finish machine crankshaft lead time: 90-95 days.

If not, then Developing New Mould: 1month for rods,cranks,pistons. Shipping by Air: 3-10 days,Shipping by Sea: 15-25 days

-

Which express you can offer?

-

Air-express: FedEx,DHL,UPS,TNT,EMS,CDEK. We could also arrange sea shipping.

-

What Forms of Payment Should Your Business Accept?

-

T/T, PayPal and West Union

-

How long does it take to get a response?

-

We will respond to you in a timely manner,welcome to leave message at contact us page.

-

What is your 4032 Aluminium chemical element?

-

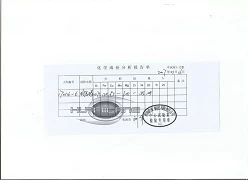

4032 chemical element including: Si: 11.0 – 13.5% Mg: 0.80 – 1.30% Cu: 0.50 – 1.30% Ni: 0.50 – 1.30% Cr: ≤ 0.10% Zn: ≤ 0.25% Fe: ≤ 1.0% Al: 81.1 – 87.2% Other each: ≤ 0.050% Other total: ≤ 0.15% You can go for our CERTIFICATION page for Hurricane 4032 piston chemical element Test Report.

-

What kind of Inspection will you do to guarantee Piston quality?

-

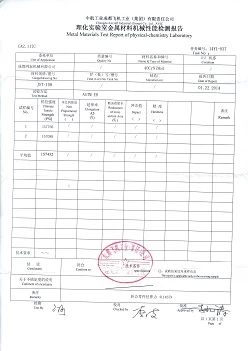

We will do: Inspection of property paramater of metal, Chemical Inspection, Mechanical Inspection, Hardness Inspection and Over sintering Inspection.

-

Can I purchase rings set for your piston together?

-

No, currently we can not provide rings set.

-Connecting-Rods-Custom-conneting-rods.jpg.webp)