- Latest Product

- News

-

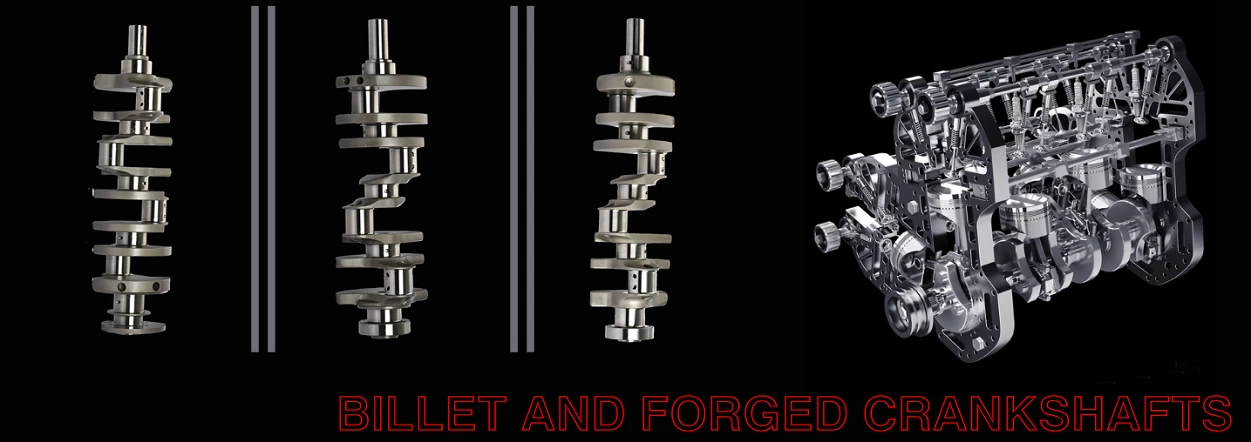

Hurricane Factory VW Air Cooled Forged Steel Crankshaft Info

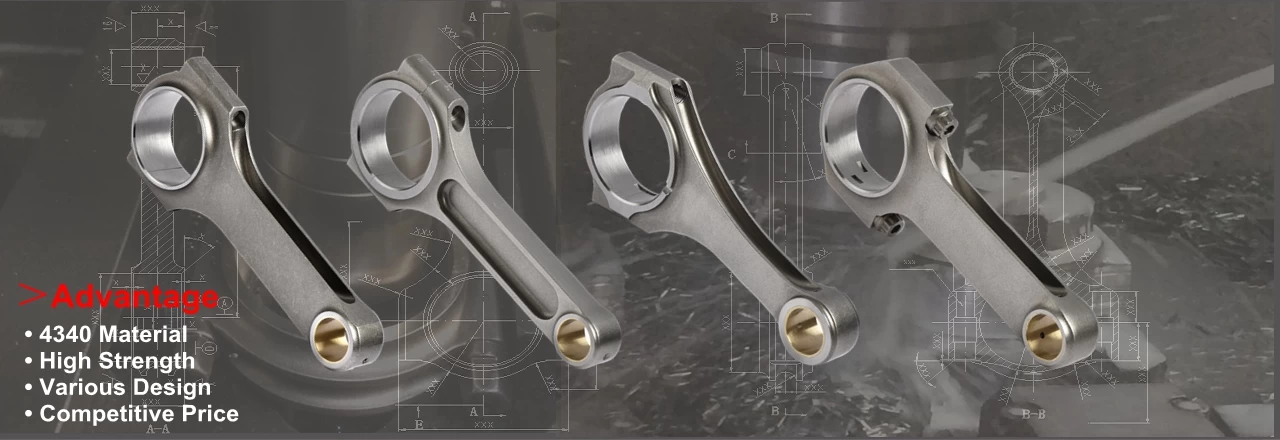

Hurricane factory manufactured in a wide variety of strokes with either VW or Chevy journals to fit your exact engine configuration. All of hurricane ...Hurricane Connecting Rod Features - Various Beam Designs

With many years experience of designing, developing , engineering and manufacturing in the connecting rods fields, Hurricane has ability to handle different customers needs on connecting rods designs . Except connecting rods shoulder and small end, Hurricane also can build various connecting rods beam style .Hurricane High Performance connecting rods - Process of machining rods

Main rods includes Chevy,Ford, Harley Davidson, VW & Audi, Opel, Honda, Nissan,Subaru, Mitsubishi, Toyota, Isuzu, Suzuki, Mazda, Buick, BMW, Chrysler & Dodge, Fiat

Here in the following process of pictures are the 13 major operations undertaken in the production of Hurricane Speed&Performance:The difference of the connecting rod manufacturing process: Forged vs Billet

Forging and billet as two different manufacturing processes to make high performance connecting rods, both can produce strong finished produc

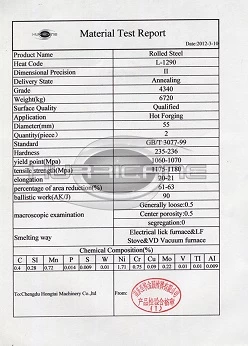

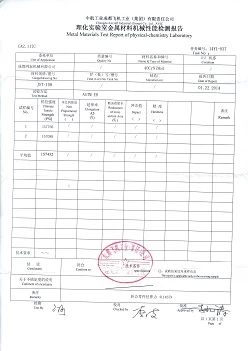

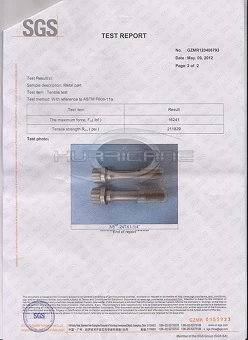

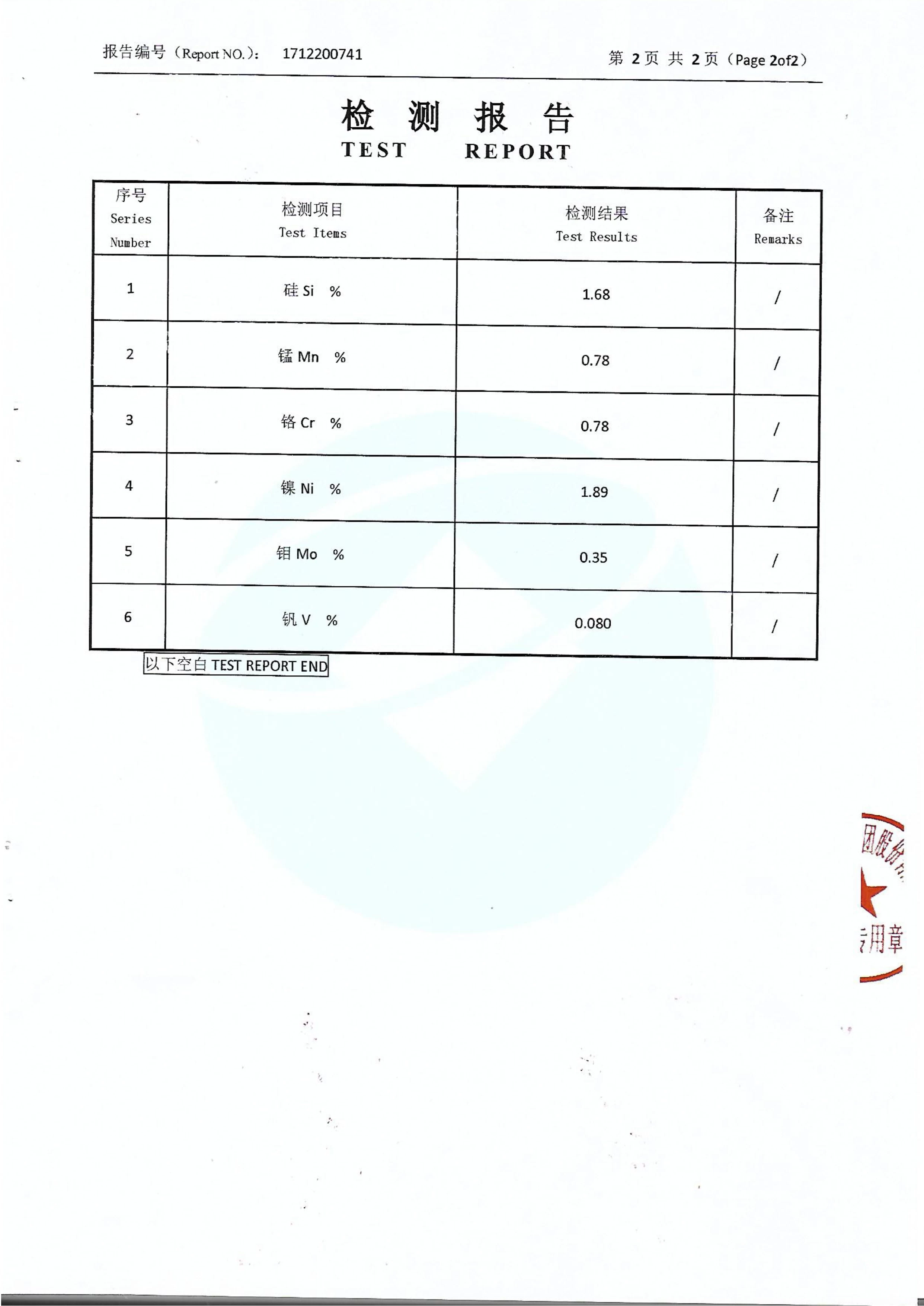

- Certifications

-

- Contact Us

- Hurricane Contact Information We believe the soul of a business is quality. Hurricane is a manufacturer of high performance automotive engine parts. W... Contact Now

Forged 4340 Chrome-Moly H-beam Connecting Rod, Honda J32 (J32A1/2/3)

- Engine Model: Honda J32 (J32A1/2/3)

- Material: Forged 4340 Steel

- Copper bush : QAL10-3-1.5

- Bolts threads : 3/8"

- Competitive Price

- Quality Assurance

- MOQ: 100pieces

- Delivery Time: If the goods are in stock , the delivery time is 1-3 days.

- If the goods are not in stock , the delivery time is 90-95 days .

- Payment Terms : T/T , Paypal , Western Union

- Keywords : Acura & Honda Rods - Hurricane Speed and Performance

- Honda J engine - Performance conrod supplier in China

- Extreme Forged H Beam Connecting Rods Acura Honda

- Honda J32 (J32A1/2/3) 6pcs/set Connecting rods factory

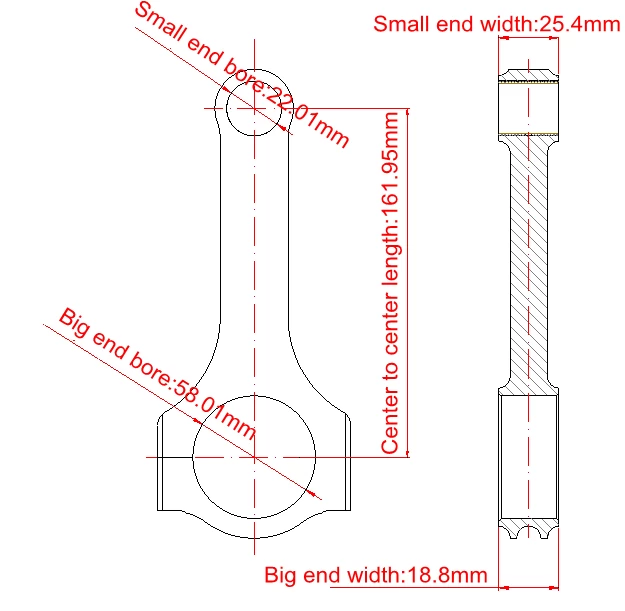

Honda J32 (J32A1/2/3) 6pcs/set Connecting rods Main Sizes

| Brand: Hurricane* |  |

| Center to Center Length: 161.95mm/6.376" | |

| Big End Bore Diameter: 58.01mm/2.284" | |

| Big End Width:18.80mm/0.740" | |

| Small End Bore Diameter:22.01mm/0.866" | |

| Small End Width: 25.4mm/1.000" | |

| Beam Style: H-beam |

Extreme Forged H Beam Connecting Rods Acura Honda J32 Features

Connecting Rod Bolt Diameter

3/8"

Approximate Connecting Rod Weight

670g

Advertised Horsepower Rating

800hp

Quantity

Sold as 6 pieces /set

Material

Forged 4340 steel

Connecting Rod Finish

Shot-peened, Polished

Pin

Bronze wrist pin bushings

Wrist Pin Style

Floating

Cap Retention Style

Cap screw

Weight Matched Set

Yes ,Balanced +/- 1g

Magnafluxed

Yes

Private Label

Yes ,available

Custom design

Custom design Yes, accept

Acura & Honda Rods - J32A1, J32A2, J32A3 Description

Hurricane connecting rods made from high tensile and fatigue resistance 4340 steel material , designed and evaluated by 3D software , 100% Computer Controlled Numeric(CNC) machined , polished and shot peened to meet high technical standard.

Fits for:

Honda J32A1:

1999-2003 Acura TL

2001-2003 Acura CL

1998-2003 Honda Inspire

Honda J32A2:

2001-2003 Acura CL Type-S

2002-2003 Acura TL Type-S

Honda J32A3:

2004-2008 Acura TL

More information about Honda J Engine

The J-series is Honda's fourth production V6 engine family introduced in 1996, after the C-series, which consisted of three dissimilar versions. The J-series engine was designed in the United States by Honda engineers. It is built at Honda's Anna, Ohio and Lincoln, Alabama engine plants.

It is a 60° V6 – Honda's existing C-series were 90° engines. The J-series was designed for transverse mounting. It has a shorter bore spacing (98 mm (3.86 in)), shorter connecting rods and a special smaller crankshaft than the C-series to reduce its size. All J-series engines are gasoline-powered SOHC 4-valve designs with VTEC variable valve timing.

One unique feature of some J-family engine models is Honda's Variable Cylinder Management (VCM) system. The system uses VCM to turn off one bank of cylinders under light loads, turning the V6 into a straight-3. Some versions were able to turn off one bank of cylinders or one cylinder on opposing banks, allowing for three-cylinder use under light loads and four-cylinder use under medium loads.

-Connecting-Rods-Custom-conneting-rods.jpg.webp)

.jpg.webp)

.jpg.webp)