Differences Between 4340 Forged Steel Cranks and 4340 Billet Steel Cranks

Rebecca Yu

http://www.hurricanerods.com

2017-08-11 19:04:09

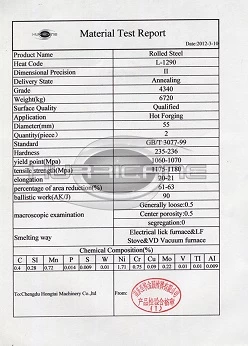

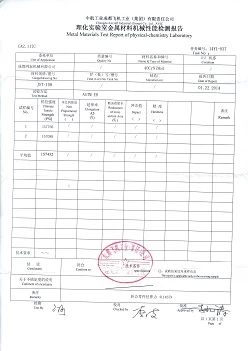

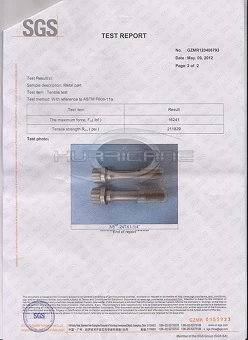

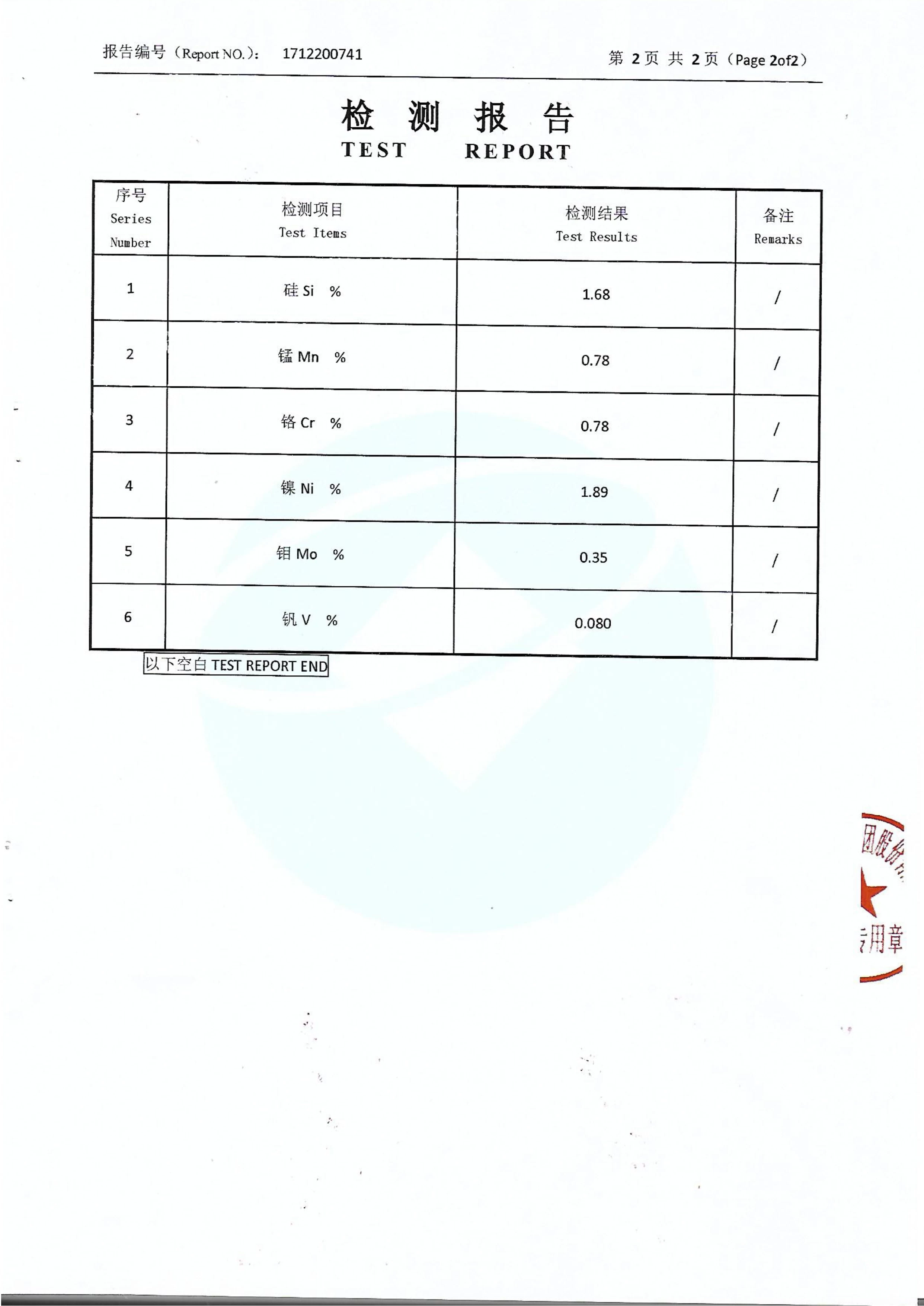

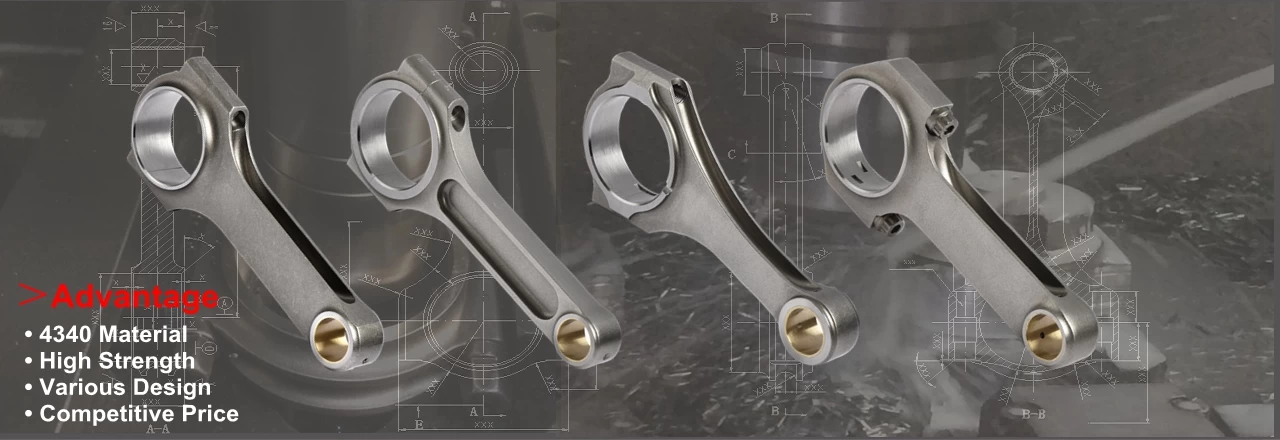

4340 steel is the most common material for crankshaft in automotive aftermarket industry . Same with 4340 steel connecting rods , there are two manufacturing processes used to produce high performance crankshaft today : forged and billet , so the 4340 crankshaft can be manufactured to 4340 steel billet crankshaft and 4340 steel forged crankshaft , we also called them as 4340 billet fully finish machine crankshaft and 4340 forged semi finsihe machine crankshaft . Here are some tips can help you to understand what the differences between billet steel crankshaft and forged steel crankshaft .

1.Manufacturing Process

The most difference between 4340 steel billet crankshaft and 4340 steel forged crankshaft is whether they produced base on dies or not .

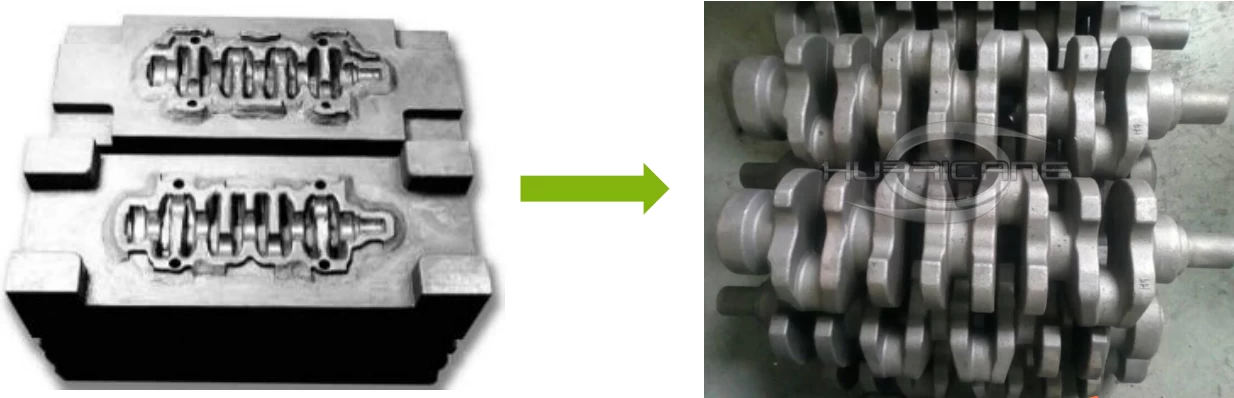

Forged crankshaft is a manufacturing process involved dies , then goes to machine , same with the pictures as below :

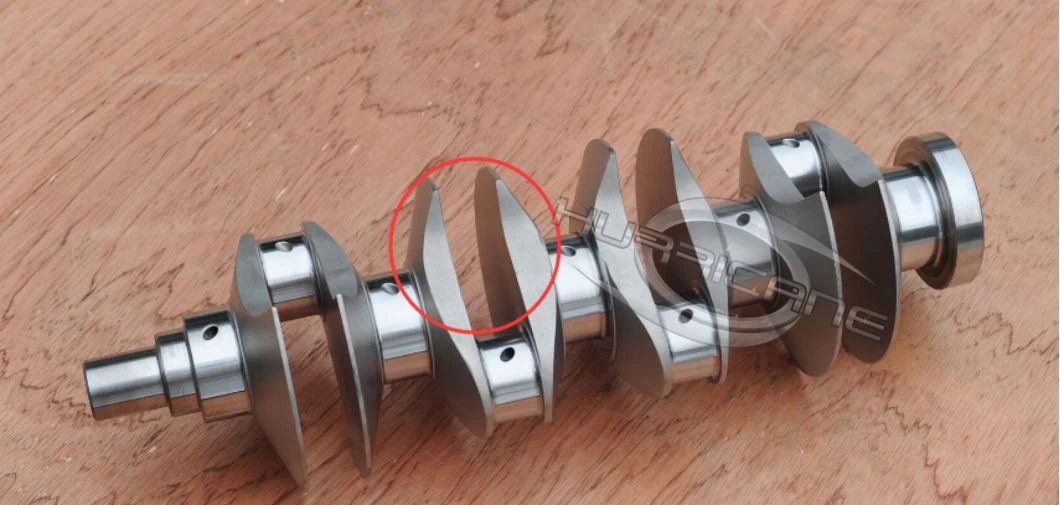

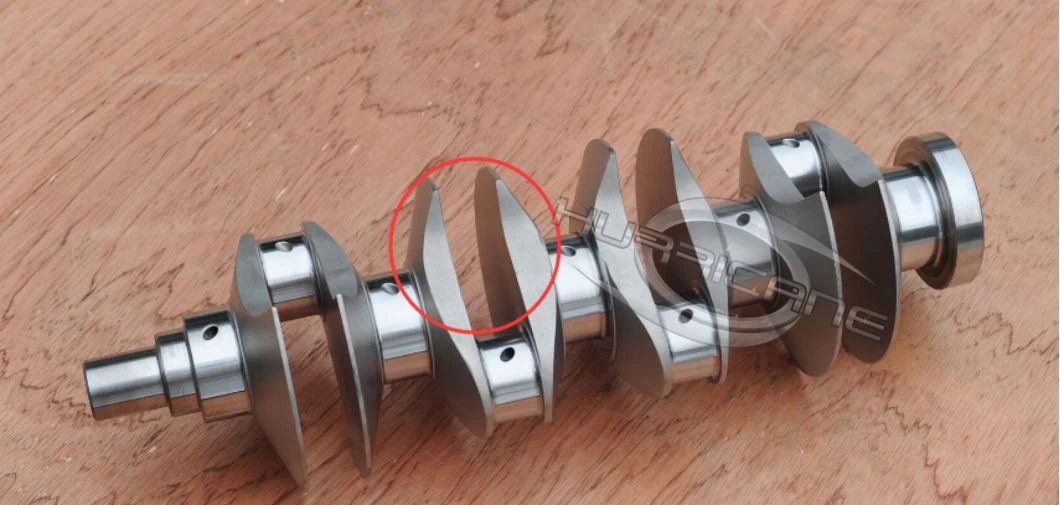

The forged crankshaft by drilling balance hole to keep balance , so it's surface is less smooth than billet crankshaft .

Forged crankshaft produced from dies, considering the expensive dies cost and dies will be wear out and replaced fininally , the initial production cost of forged cranksahft is much higher , but if it can achieve large volume manufacturing, it is worth to invest. Billet crankshaft would not depend on dies , but it usually enginered with small batches or in customize manufacturing, more time and labor will be required to spend on design, machine setup and re-assembly, so that billet crankshaft will be expensive than forged crankshaft with same 4340 steel material.

1.Manufacturing Process

The most difference between 4340 steel billet crankshaft and 4340 steel forged crankshaft is whether they produced base on dies or not .

Forged crankshaft is a manufacturing process involved dies , then goes to machine , same with the pictures as below :

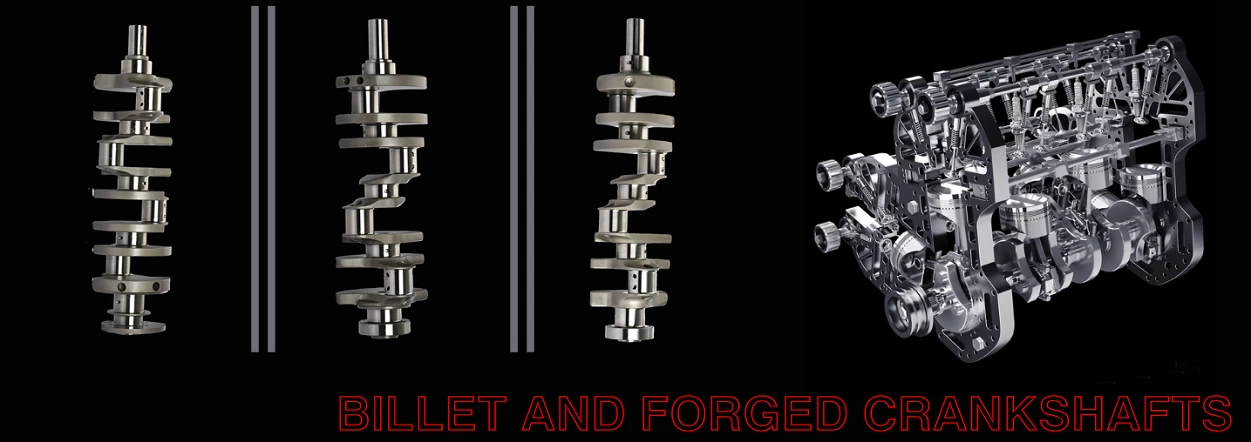

Billet cranskhaft starts out with a large cylindrical ingot of steel, then goes to final machining, same with pictures as below :

Both processes can produce very strong finished crankshaft when quality manufacturing processes and materials are used. But because developing dies will cost too much , and it more suits for large volume manufacturing , so billets mostly used on where the one has no large volume and don’t want to invest on a forged die .

2.Balance

The forged crankshaft by drilling balance hole to keep balance , so it's surface is less smooth than billet crankshaft .

The process flow of billet crankshaft is very special, perfect fan plate design and strict tech standard to help the billet crankshaf balance well in the process of high speed rotation, more importantly , and it's surface are very smooth and looks beautiful .

Note : All the Hurricane crankshaft will do balance test in factory , and the final unbalance remaining ≦6g.cm

3.Production Cost

Forged crankshaft produced from dies, considering the expensive dies cost and dies will be wear out and replaced fininally , the initial production cost of forged cranksahft is much higher , but if it can achieve large volume manufacturing, it is worth to invest. Billet crankshaft would not depend on dies , but it usually enginered with small batches or in customize manufacturing, more time and labor will be required to spend on design, machine setup and re-assembly, so that billet crankshaft will be expensive than forged crankshaft with same 4340 steel material.

By the way , Hurricane will produce a large volume 4340 steel forged crankshaft for GM Chevy LS1 engines recently, include 4.000" stoke, 4.125" stroke , 3.900" stroke and etc , any inquiry for these models, please feel free email us .

-Connecting-Rods-Custom-conneting-rods.jpg.webp)