- Latest Product

- News

-

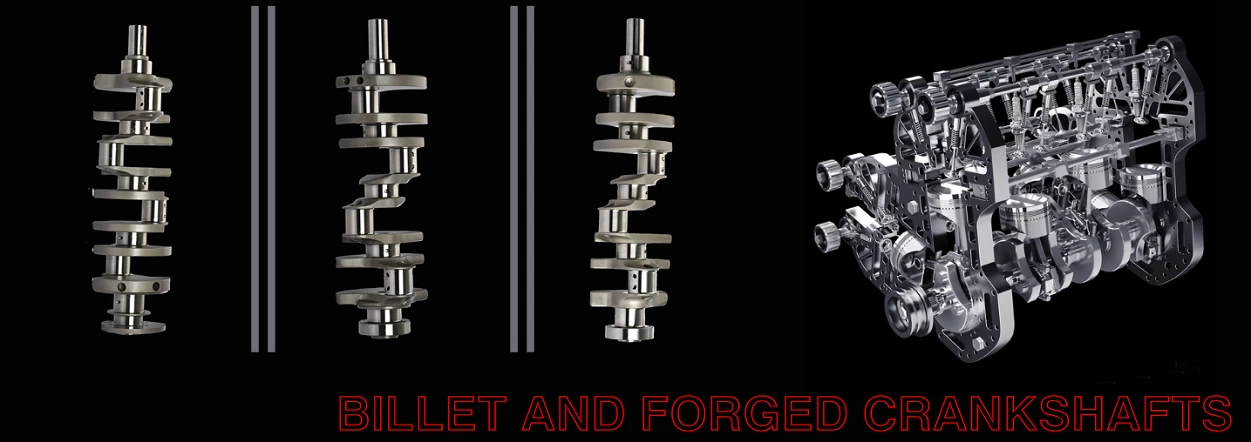

Hurricane Factory VW Air Cooled Forged Steel Crankshaft Info

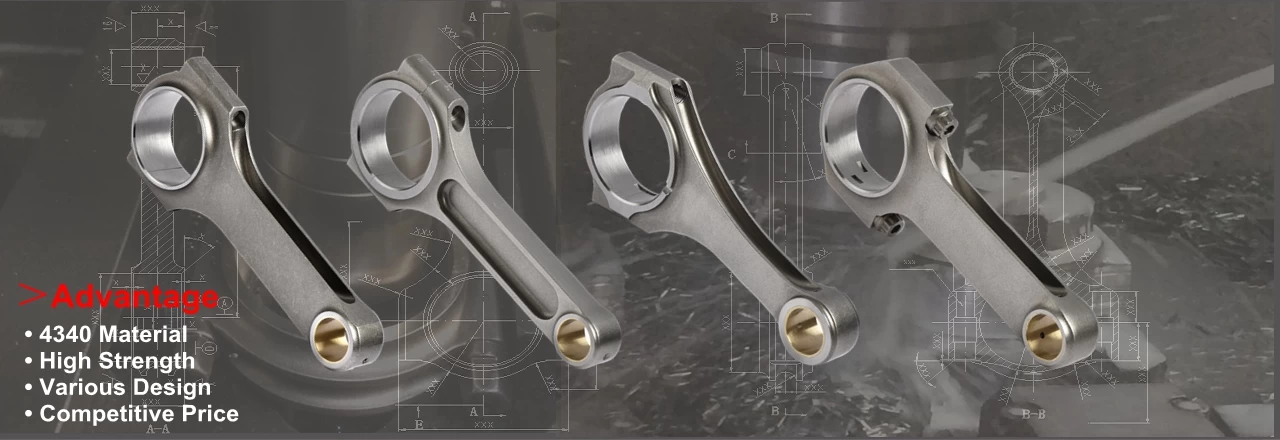

Hurricane factory manufactured in a wide variety of strokes with either VW or Chevy journals to fit your exact engine configuration. All of hurricane ...Hurricane Connecting Rod Features - Various Beam Designs

With many years experience of designing, developing , engineering and manufacturing in the connecting rods fields, Hurricane has ability to handle different customers needs on connecting rods designs . Except connecting rods shoulder and small end, Hurricane also can build various connecting rods beam style .Hurricane High Performance connecting rods - Process of machining rods

Main rods includes Chevy,Ford, Harley Davidson, VW & Audi, Opel, Honda, Nissan,Subaru, Mitsubishi, Toyota, Isuzu, Suzuki, Mazda, Buick, BMW, Chrysler & Dodge, Fiat

Here in the following process of pictures are the 13 major operations undertaken in the production of Hurricane Speed&Performance:The difference of the connecting rod manufacturing process: Forged vs Billet

Forging and billet as two different manufacturing processes to make high performance connecting rods, both can produce strong finished produc

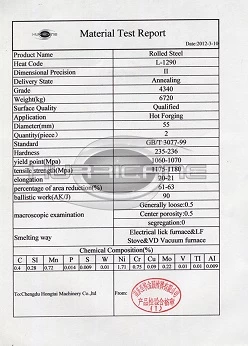

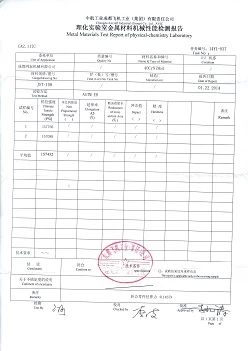

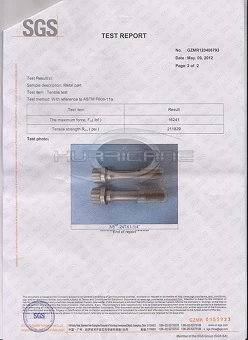

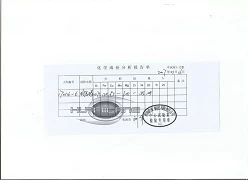

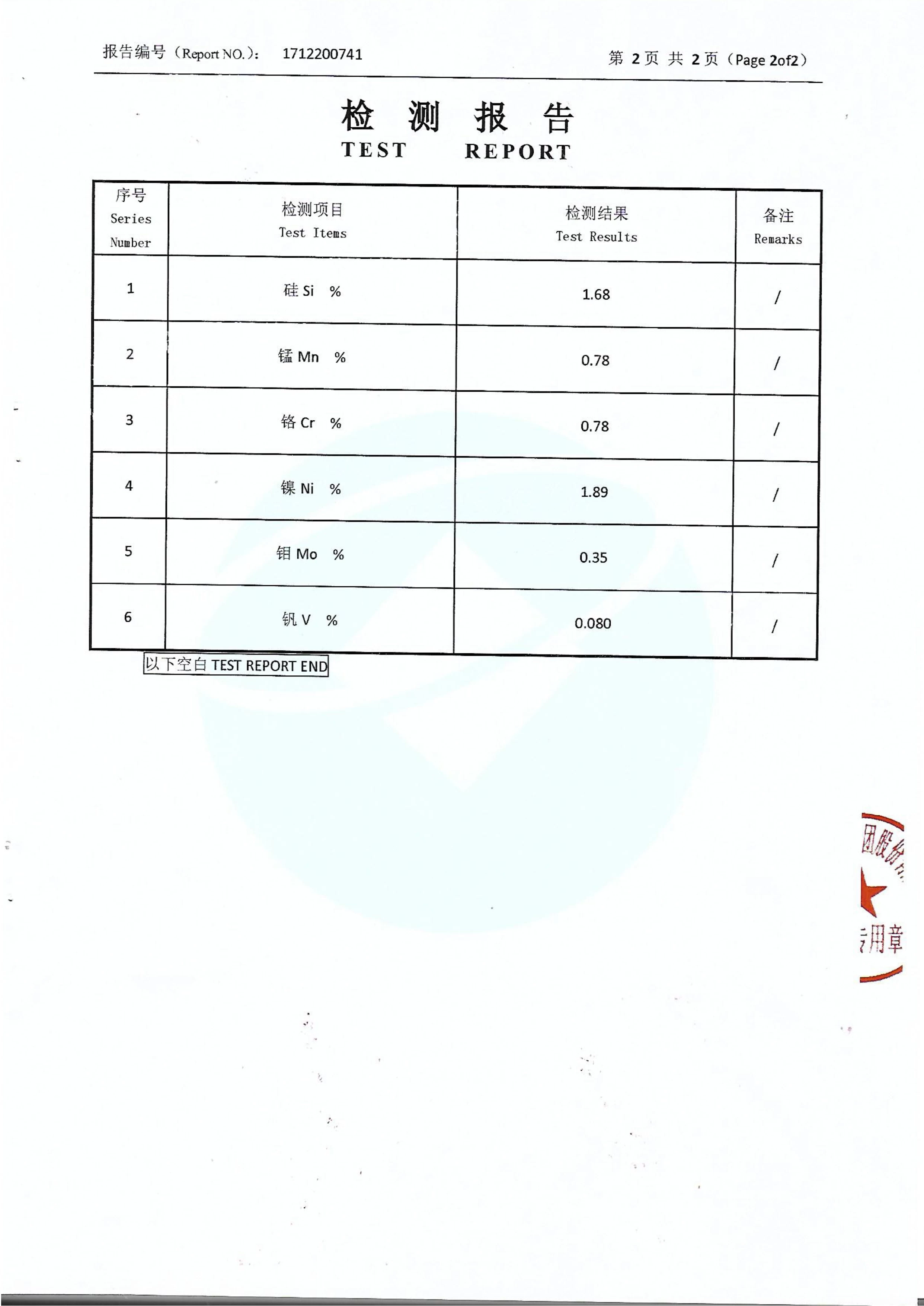

- Certifications

-

- Contact Us

- Hurricane Contact Information We believe the soul of a business is quality. Hurricane is a manufacturer of high performance automotive engine parts. W... Contact Now

Hurricane Speed & Performance -4340 Chrome-Moly F20C/S2000 X-beam Connecting Rods

- Competitive Price

- 4340 steel/40CrNiMoA/EN24

- CNC machine

- Custom rods

- Quality Assurance

- MOQ:80pieces

- Delivery Time: If the goods are in stock , the delivery time is 1-3 days.

- If the goods are not in stock , the delivery time is 60-65 days .

- Payment Terms : T/T , Paypal , Western Union

- Keywords:Honda f20c connecting rods for sale

- High performance 4340 steel rods supplier

- Manufacturing engin conrods in China

- X-beam Forged Honda F20C rods for racing engine

Brand: Hurricane

Engine: Honda F20C/S2000

Part Type: Connecting Rods

Center to Center Length: 152.98mm/6.023"

Big End Bore Diameter: 51mm/2.008"

Big End Width: 23.85mm/0.939"

Small End Bore Diameter: 23mm /0.906"

Small End Width: 22mm/0.866"

Beam Style: X-beam

Connecting Rod Bolt Diameter: 3/8 "

Approximate Connecting Rod Weight: 640g/piece

Advertised Horsepower Rating: 900hp

Quantity: Sold as 4pieces /set

Material: Forged 4340 steel

Connecting Rod Finish: Shot-peened, Polished

Pin: Bronze wrist pin bushings

Wrist Pin Style: Floating

Cap Retention Style: Cap screw

Weight Matched Set: Yes ,Balanced +/- 1g

Magnafluxed: Yes

Private Label: Yes ,available

Custom design: Yes, accept

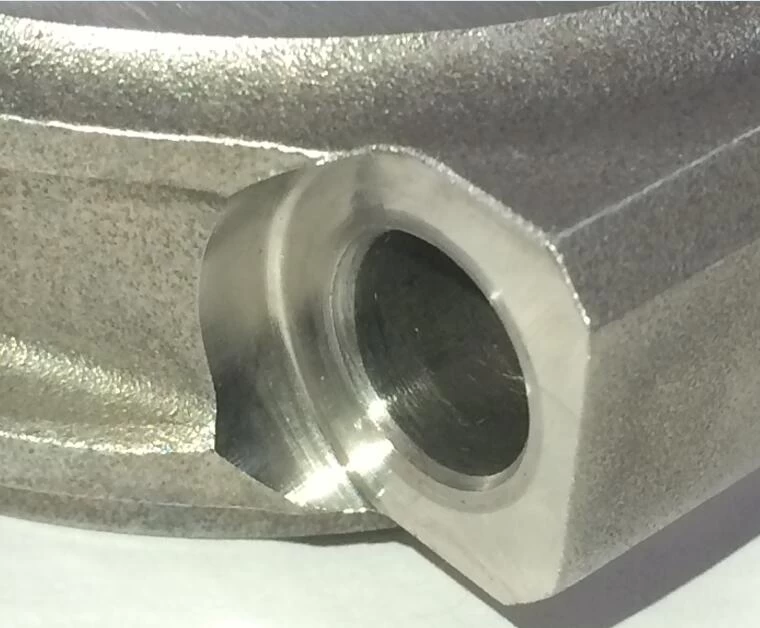

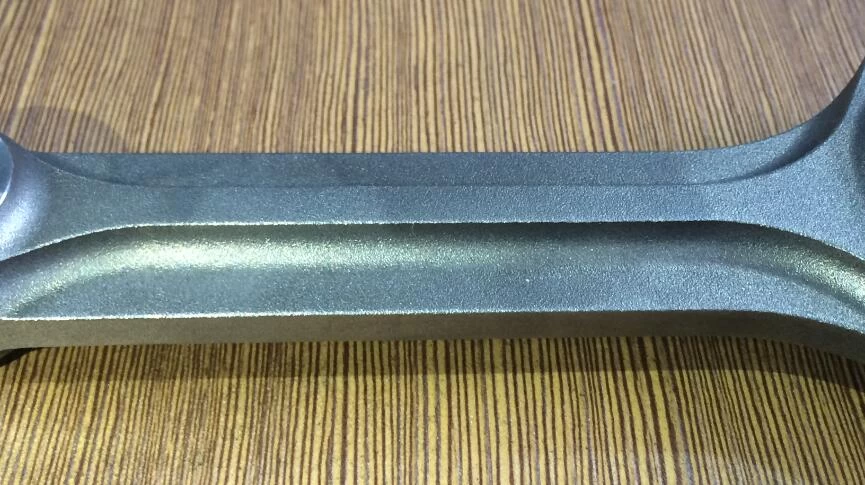

2.Big end surface effect. the surface is very smooth , the R part is mellow and full.It is hard to see the tool vestige.

3.shot-peening effect. we are strict to select steel shot. We only use the cleanest shot which has the most suitable size. The result is our rods`surface is very bright and smooth.

4.Bolt seat.you can see the roof's arch is mellow and full. Only CNC can reach this degree.

6. Big end arch part surface is also very smooth and we make the shoulder into arc shaped.

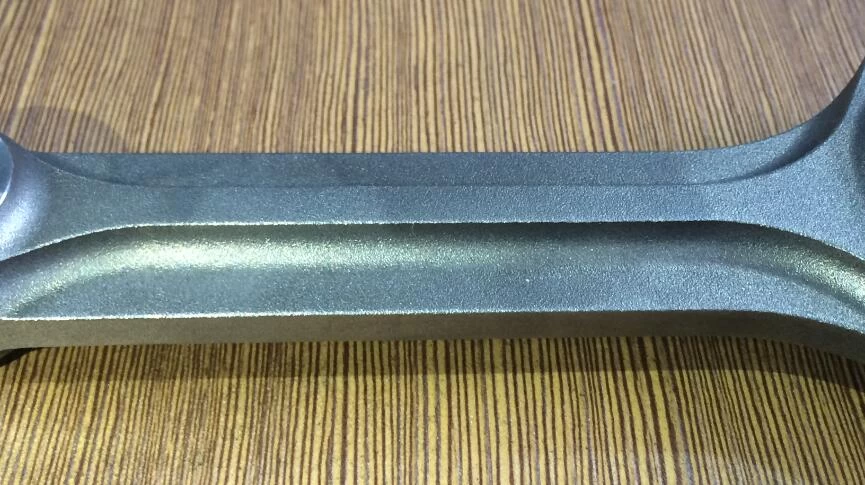

7. X–beam effect. as a result of twice maching by CNC, it is very smooth.

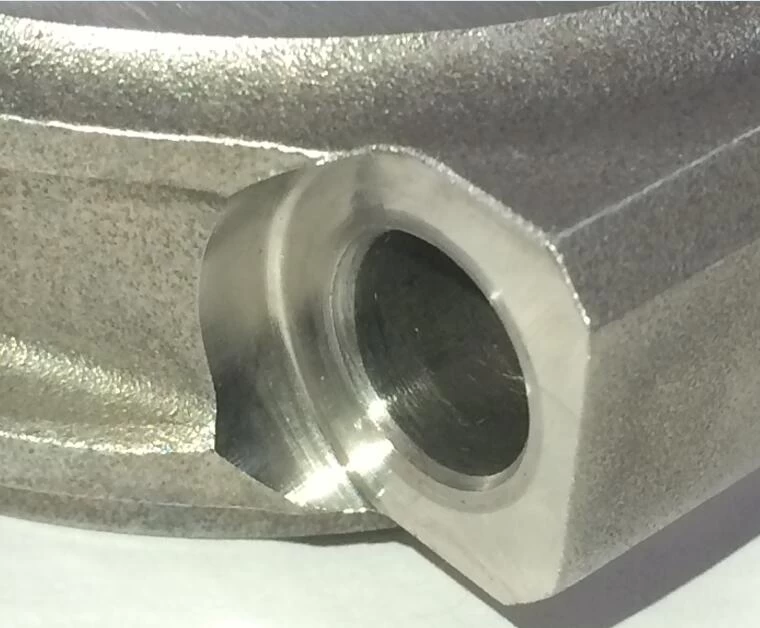

8.Pin end arch part surface is very smooth, it is hard to see the tool vestige.

9.Cooper bush of the pin end. It is smooth and beautiful.

10.Generally,2.5mm-3mm diameter oil hole on the pin end.

Engine: Honda F20C/S2000

Part Type: Connecting Rods

Center to Center Length: 152.98mm/6.023"

Big End Bore Diameter: 51mm/2.008"

Big End Width: 23.85mm/0.939"

Small End Bore Diameter: 23mm /0.906"

Small End Width: 22mm/0.866"

Beam Style: X-beam

Connecting Rod Bolt Diameter: 3/8 "

Approximate Connecting Rod Weight: 640g/piece

Advertised Horsepower Rating: 900hp

Quantity: Sold as 4pieces /set

Material: Forged 4340 steel

Connecting Rod Finish: Shot-peened, Polished

Pin: Bronze wrist pin bushings

Wrist Pin Style: Floating

Cap Retention Style: Cap screw

Weight Matched Set: Yes ,Balanced +/- 1g

Magnafluxed: Yes

Private Label: Yes ,available

Custom design: Yes, accept

Honda Series Rods are forged from select 4340 chromoly steel and feature a X-beam design, resulting in the ultimate strength-to-weight ratio. 4340 chromoly is one of the strongest materials available, however, not all 4340 chromoly is the same. Such as, Hurricane relies on extensive material testing and works closely with its foundry to produce high-quality rods at an affordable price. Comprehensive heat-treating, tempering, and shot-peening processes together ensure that each Honda Series Rod remains consistent and strong. Finally, each rod with a blance weight ensure integrity and that each process has been completed thoroughly and according to rigid specifications.

Hurricane Speed and Performance Connecting rods features:

1.Smooth finish of BE BORE surface .it`s precision is within 0.01mm after honing. It is even used to be your mirror.

2.Big end surface effect. the surface is very smooth , the R part is mellow and full.It is hard to see the tool vestige.

3.shot-peening effect. we are strict to select steel shot. We only use the cleanest shot which has the most suitable size. The result is our rods`surface is very bright and smooth.

4.Bolt seat.you can see the roof's arch is mellow and full. Only CNC can reach this degree.

5. The bolt hole and thread are made by CNC and Precise cutting-tool.You can't find any tool vestige even on the bolt hole surface.

6. Big end arch part surface is also very smooth and we make the shoulder into arc shaped.

7. X–beam effect. as a result of twice maching by CNC, it is very smooth.

8.Pin end arch part surface is very smooth, it is hard to see the tool vestige.

9.Cooper bush of the pin end. It is smooth and beautiful.

10.Generally,2.5mm-3mm diameter oil hole on the pin end.

-Connecting-Rods-Custom-conneting-rods.jpg.webp)